How the Optical Fibre Diameter Analyser Plays a Vital Role in Enhancing Fibre Optic Technologies

Just How an Optical Fibre Diameter Analyser Improves Top Quality Control in Fibre Production

The assimilation of an Optical Fibre Diameter Analyser right into Fibre manufacturing processes represents a significant development in quality assurance techniques. By using real-time, accurate dimensions of Fibre sizes, this innovation addresses the essential requirement for consistency in manufacturing standards. With its capability to swiftly determine discrepancies and punctual corrective actions, the analyser not just improves item dependability yet also adds to overall functional performance. As industries increasingly focus on quality and conformity, recognizing the full effect of such innovations ends up being crucial. What implications could this have for the future of Fibre production?

Value of Fibre Diameter Measurement

Precise dimension of Fibre Diameter is essential in the field of optical Fibre technology, as it straight affects the efficiency and integrity of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying capability, attenuation, and overall transmission efficiency. Accuracy in gauging Fibre Diameter guarantees that the optical homes are maintained within defined resistances, which is crucial for ideal signal integrity.

Variations in Fibre Diameter can lead to increased losses as a result of spreading and modal diffusion, influencing the high quality of data transmission. In high-speed interaction systems, such disparities can lead to significant degradation of signal top quality, causing data errors and decreased efficiency. In addition, constant Fibre Diameter is vital for compatibility with connectors and splicing modern technologies, which are important parts of Fibre optic networks.

Quality control procedures in Fibre manufacturing heavily depend on accurate Diameter measurements to make certain compliance with sector standards. By applying robust dimension methods, producers can boost product integrity, minimize waste, and enhance overall system performance. Hence, the significance of Fibre Diameter dimension can not be overstated, as it works as a keystone in the improvement of optical Fibre innovation and its applications in modern-day communication networks.

Exactly How the Analyser Functions

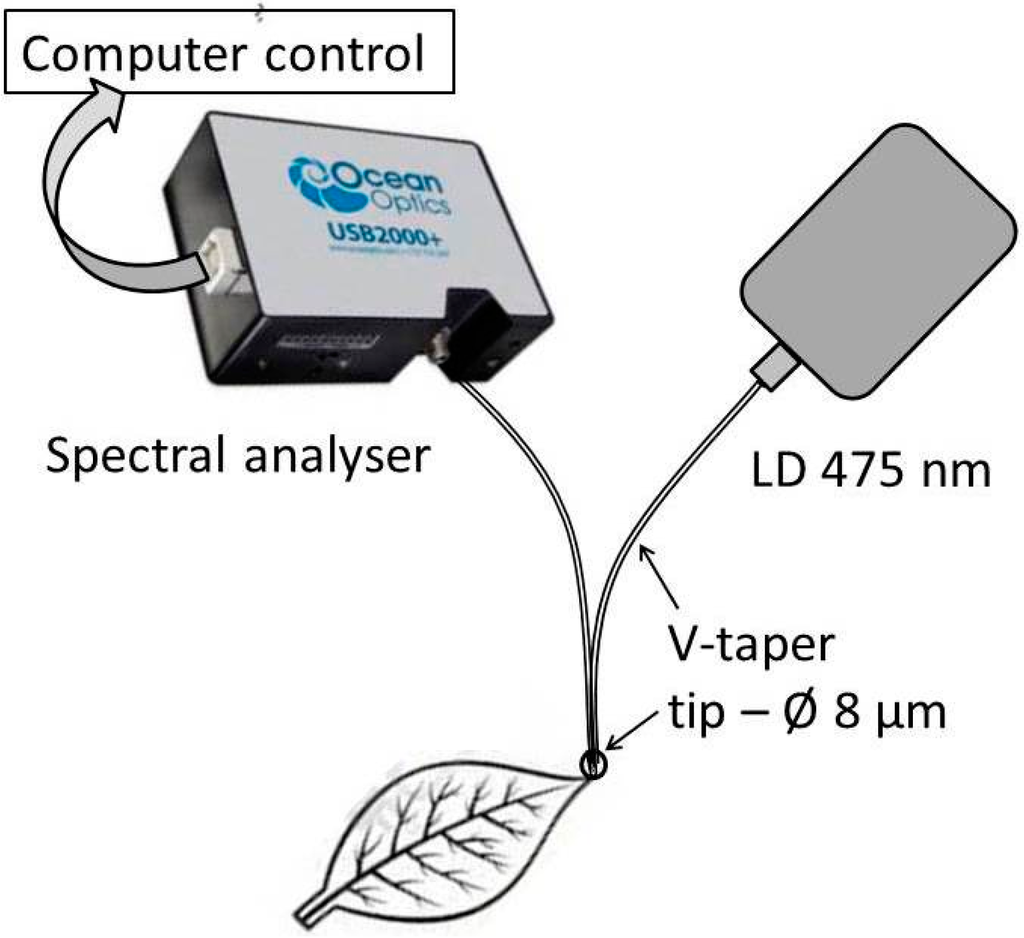

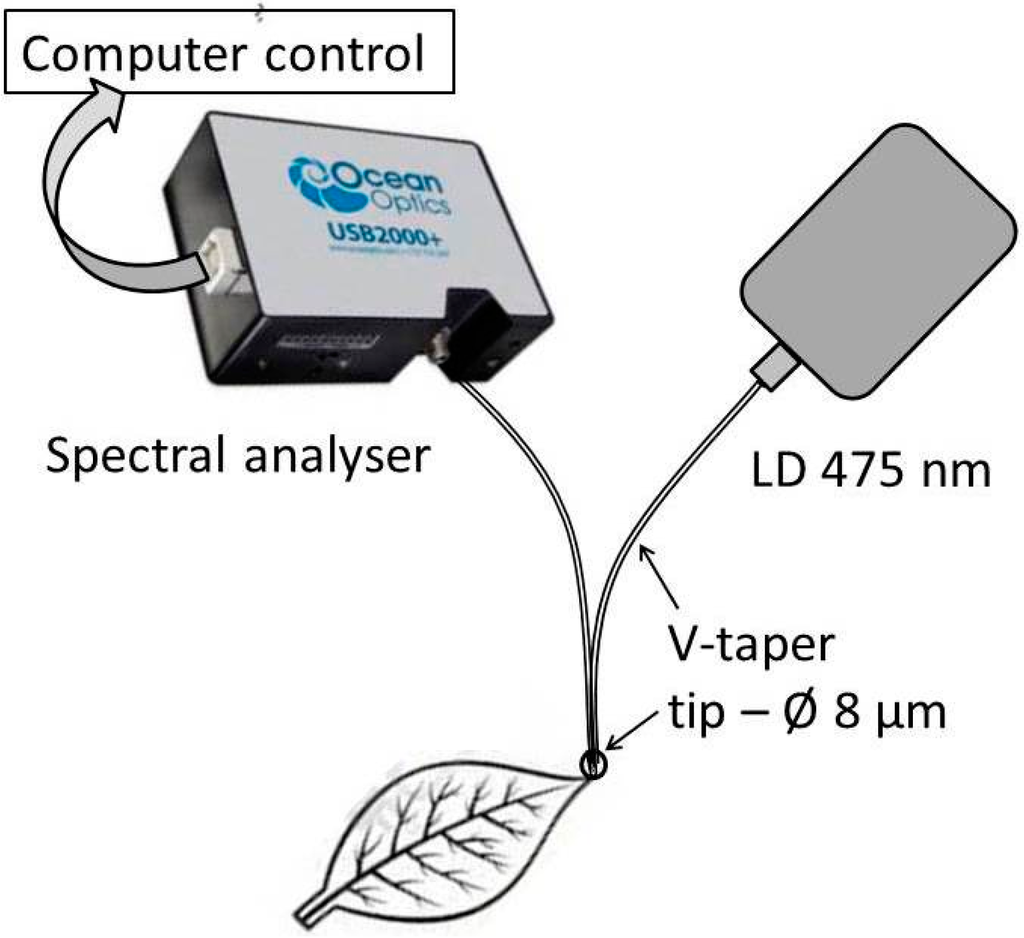

The effective dimension of Fibre Diameter counts on advanced analytical methods that ensure precision and dependability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser uses a combination of laser innovation and progressed photo processing algorithms to precisely analyze the Diameter of fibres as they are created

At first, a laser beam is directed at the moving Fibre, developing a cross-sectional darkness. The analyser records this shadow using high-resolution cams placed tactically along the production line. The captured pictures are then processed in real-time to identify the Fibre's Diameter with remarkable accuracy.

The system uses innovative formulas that make up numerous variables, consisting of variations in light intensity and ecological problems, to improve dimension dependability. It can find minute changes in Diameter, such as variations that could occur during the manufacturing procedure.

Moreover, the analyser is qualified of managing numerous fibres all at once, boosting throughput without endangering accuracy. By offering immediate comments on the Diameter, the Optical Fibre Diameter Analyser plays an essential duty in preserving stringent top quality control requirements, guaranteeing that the final item fulfills industry specs and client needs.

Benefits of Real-Time Monitoring

While traditional techniques of keeping an eye on Fibre Diameter frequently involve lengthy post-production checks, real-time tracking substantially boosts the efficiency and quality of optical Fibre production. optical fibre diameter analyser. This aggressive strategy permits manufacturers to identify discrepancies in Fibre Diameter as they happen, instead of waiting until production is full to analyze high quality

By continually determining the Diameter throughout production, manufacturers can make sure that the fibers fulfill strict specs, leading to decreased irregularity and enhanced uniformity. Real-time tracking likewise allows instant corrective activities to be taken, decreasing waste and protecting against faulty fibres from getting in the supply chain.

Furthermore, this technology assists in enhanced data collection and evaluation, giving insights right into manufacturing fads and potential locations for improvement. Such data-driven decision-making empowers manufacturers to enhance processes and keep high criteria of high quality control.

In enhancement, real-time tracking fosters a society of continuous renovation within the manufacturing environment. Workers are more involved when they can see the influence of their operate in real-time, resulting in redirected here enhanced liability and a dedication to excellence. Generally, the application of real-time surveillance systems in optical Fibre production equates to superior product quality and boosted client fulfillment.

Effect On Manufacturing Performance

Carrying out optical Fibre Diameter analysers dramatically boosts production performance by simplifying the production process. These devices promote continual monitoring of Fibre Diameter, enabling manufacturers to find variances in real-time. By identifying incongruities without delay, production lines can be changed swiftly, reducing downtime and reducing the possibility of generating malfunctioning products.

Furthermore, the assimilation of these analysers into the production process enables better source allocation. With accurate Diameter dimensions, drivers can maximize material usage, making sure that sources are not squandered on problematic fibres. This precision additionally adds to much less rework and scrap, ultimately lowering production expenses.

The automation given by optical Fibre Diameter analysers decreases reliance on hand-operated assessments, which are vulnerable and commonly time-consuming to human error. As a result, staff members can concentrate on more tactical tasks, enhancing general efficiency.

Furthermore, the data produced from these analysers can educate process improvements and help with much better decision-making. By assessing trends in Fibre Diameter variations, makers can carry out aggressive actions to enhance production strategies and maintain consistent top quality. In summary, optical Fibre Diameter analysers play a vital function in boosting production performance, bring about higher top quality result and increased earnings.

Study and Success Stories

Throughout numerous industries, situation researches highlight the transformative effect of optical Fibre Diameter analysers on manufacturing procedures. One prominent instance is a leading telecoms business that faced obstacles with irregular Fibre diameters, bring about increased denial rates. By incorporating an optical Fibre Diameter analyser, the firm achieved real-time monitoring of Fibre dimensions, causing a 30% decrease in defects and significant expense savings.

Moreover, a research study establishment concentrating on innovative materials made use of optical Fibre Diameter analysers to refine their experimental processes. The analyser's ability to his response supply in-depth understandings right into Fibre consistency made it possible for the development of cutting-edge products with improved performance attributes.

These success stories underscore the important duty of optical Fibre Diameter analysers in improving top quality control, boosting production performance, and driving development throughout varied sectors.

Final Thought

In final thought, the Optical Fibre Diameter Analyser plays a pivotal function in boosting quality control within Fibre production. As demonstrated via various situation research studies, the analyser proves important for accomplishing remarkable item high quality in Fibre production.

The implementation of optical Fibre Diameter analysers permitted for rigid quality control, guaranteeing that the generated fibres met exacting market criteria.In conclusion, the Optical Fibre Diameter Analyser plays a critical duty in improving high quality control within Fibre production.